The resurgence of the high speed VMC with pallet changer (APC)

Over the last 12 months, Feeler vertical machining centres with automatic pallet changer (APC) have been in great demand.

With an increase in cobot and robot automation, to maximise spindle run time, the pallet change machine allows all the unload, clean-down and re-load to take place while the machine is still running.

This offers a more robust solution to the process giving the robot plenty of time to ensure the automated load is clean and trouble free without having to rush the cycle. When compared against single pallet machines-robot configurations, the automatic door isn’t even fully open by the time an APC machine is already cutting metal on the next pallet.

This benefit is most apparent when multi loading a number of components per pallet, takt times can be massively reduced if mass producing small/medium sized components when you multi load a pallet and your load/unload time is as long as it takes for the pallets to swap over, pallet change times of just 6 to 10 seconds, depending on the size of the machine.

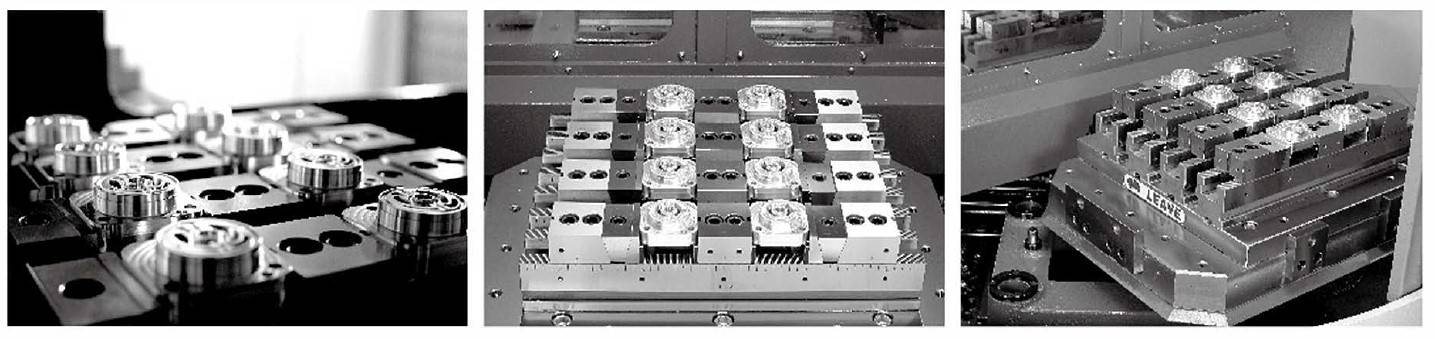

Feeler multi load utilising Rotary Hydraulic interface for Hydraulic clamping.

If you’re interested to know how you can improve takt times on high volume parts, give TDT a call and we should be able to quickly estimate increase in volume over an existing machining process.

TDT offer the Feeler VMX high speed vertical machining centres with APC built in.

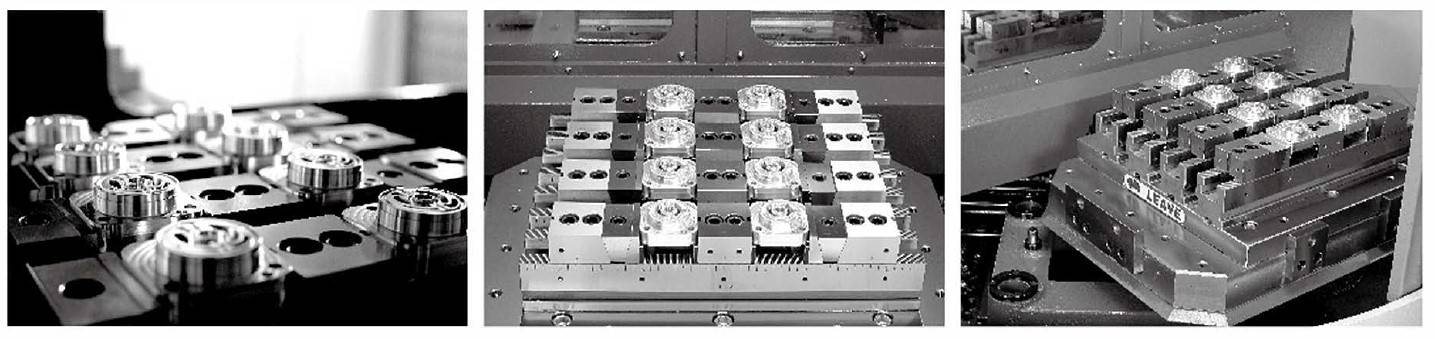

Feeler APC configuration with swing changeover

Feeler VMX580 APC

The larger Feeler VMX 820 APC TDT UK