For Engineers Who Think Big: Witness the Build of Laguns’ Largest (for now) UK Installation

Big Machines for Big Jobs. See How We Deliver on a Monumental Scale.

The successful delivery and ongoing assembly of the UK’s inaugural Lagun ML floor-type bed mill represent a significant advancement in our clients manufacturing capabilities. This complex process, anticipated to take approximately six weeks, is a testament to the meticulous planning and collaborative efforts of the professionals involved.

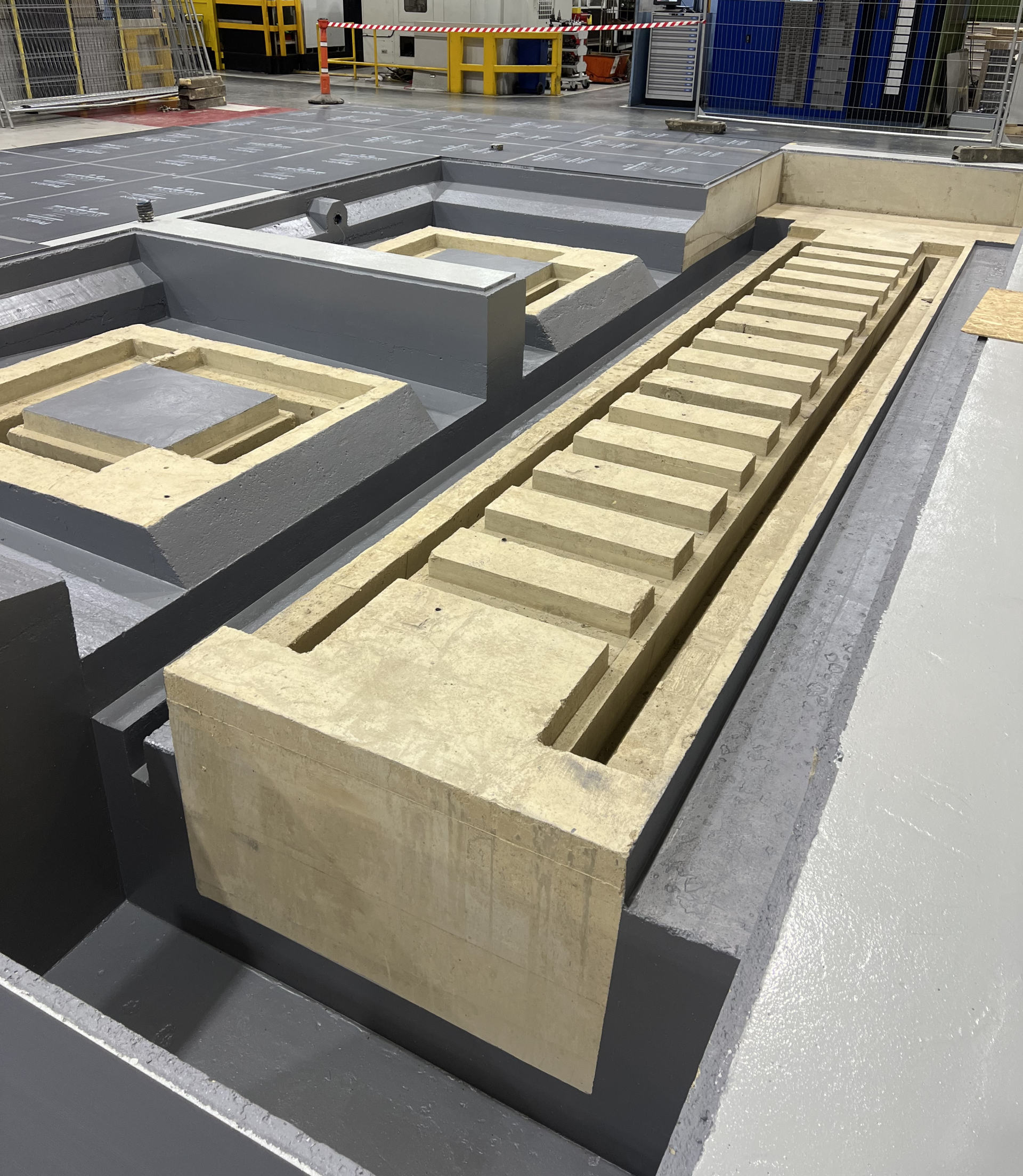

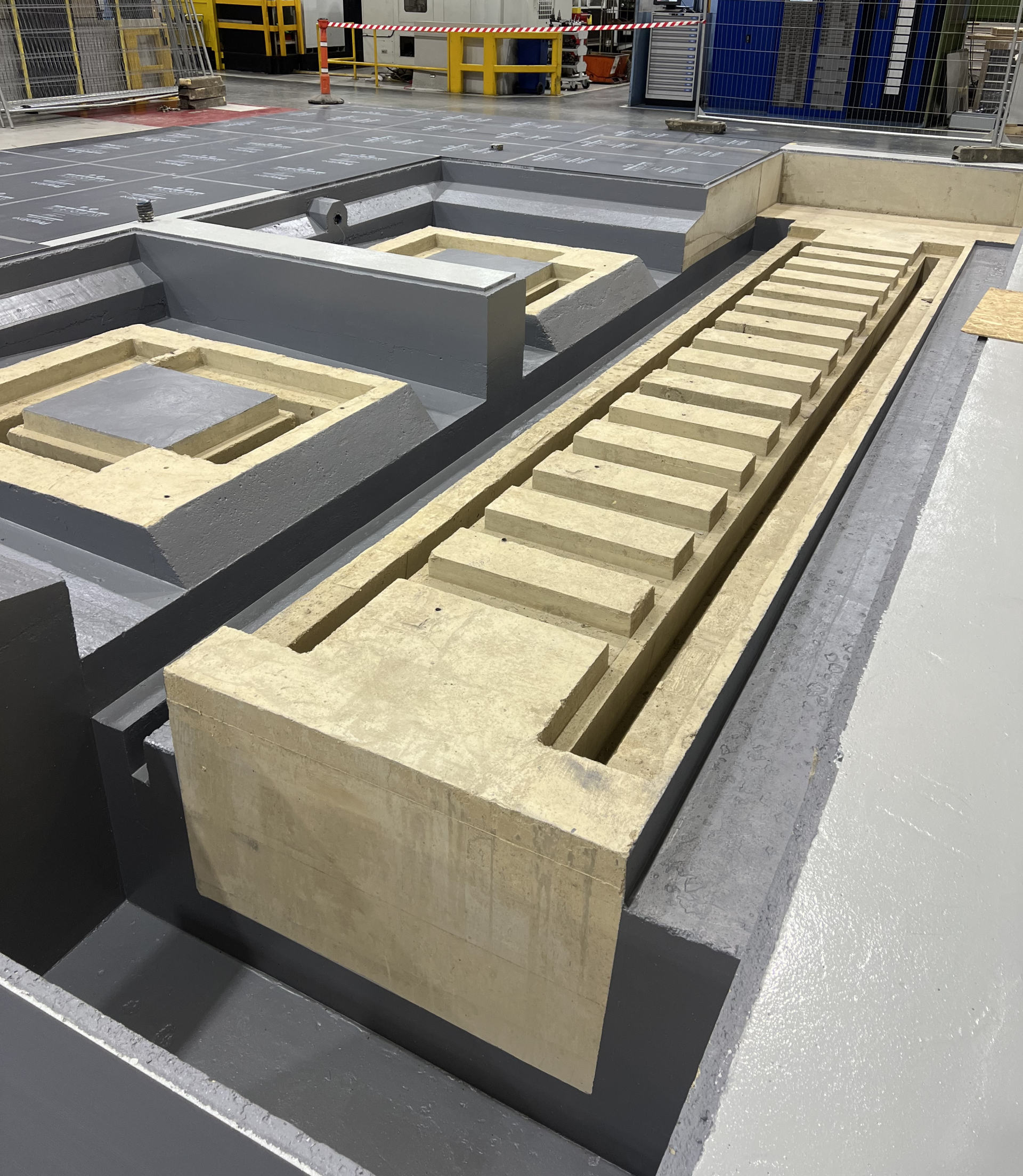

Foundation Preparation

The journey commenced with the construction of a robust foundation, essential for supporting the substantial weight and operational precision of the Lagun ML machine. This phase involved extensive groundwork, including excavation and the pouring of reinforced concrete, to create a stable base capable of withstanding the machine’s demands. The team at MSP Construction played a pivotal role in this stage, ensuring that every detail met the stringent specifications required for such a formidable installation. Click here to see previous blog on the foundation.

Painted Foundation for Lagun ML6

Delivery and Unpacking

Transporting the Lagun ML machine components required careful coordination due to their considerable size and weight. Specialized logistics were employed to safely deliver the parts to the installation site. Upon arrival, each component underwent a thorough inspection to verify its condition and adherence to quality standards before assembly commenced.

Lagun ML arriving on three lorries from Spain

Assembly Process

The assembly of the Lagun ML machine is a sequential and collaborative endeavour with decades of experience from the team involved, a special shout out to Midland Machinery (Heavy Lift) Ltd.

Bed and Column Installation: The process begins with positioning the machine’s bed, designed with strong internal reinforcement ribs for high stability during machining. Following this, the column is mounted onto the carriage, which moves over the bed on linear guide tracks, ensuring precise movement along the X, Y, and Z axes.

Lagun Base Levelling Elements

Position Lagun Base

Lagun Base anchor bolts

Come back for more updates during the machine build.

Team Collaboration

This intricate assembly process is a collaborative effort among engineers, technicians, and support staff. Their combined expertise ensures that each component is installed with precision, adhering to the highest standards of quality and safety. The team’s dedication is evident in their meticulous attention to detail, from the initial foundation work to the final calibration of the machine.

Anticipation for Operational Phase

As the assembly progresses towards completion, anticipation builds for the operational phase. The Lagun ML floor-type bed mill is poised to enhance manufacturing capabilities, offering high-capacity, precision-driven performance tailored for versatility and efficiency. This installation not only signifies a leap forward in technological capability but also highlights the exceptional teamwork and expertise of all individuals involved in bringing this project to fruition.

For more information on the Lagun ML floor-type bed mill and its applications, please visit TDT Machine Tools’ official website.