Engineering Masterpiece: Witness the 3-Week Assembly of a 5m x 4m Kafo Double Column Machining Centre in Just 2 Minutes

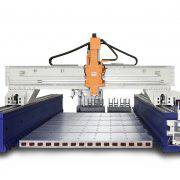

Imagine compressing three weeks of meticulous effort, precision, and teamwork into a mere two minutes. This is exactly what you witness when you watch the time-lapse of a 5m x 4m Kafo Double Column machining centre being installed by TDT Machine Tools. The video encapsulates the essence of modern engineering, showcasing the seamless coordination and expertise required to assemble such a sophisticated piece of machinery

The journey begins with the arrival of container lorries. Over the span of two days, box after box is delivered, each one containing a piece of the intricate puzzle that will soon become a fully operational Kafo double column machining centre. The sheer scale of the operation is immediately evident as crates of various sizes are carefully unloaded. These crates are not just boxes; they are containers of precision-crafted parts.

The first consignment, so big, it took two versa-lifts to take it off the flat-rack.

Box after box arrives over two days.

The first box is as wide as the factory!!

The boxes are carefully unloaded by engineers who have decades of experience under their belts building machines.

As the time-lapse progresses, you can see the transformation taking place. The foundation is laid a month in advance of the machine delivery, giving it time to set, providing a stable base for the colossal machine. This step is critical, as the precision and effectiveness of the machining centre depend on the stability and alignment of its base. Engineers meticulously measure and adjust, ensuring that everything is perfectly level before proceeding to the next steps.

TDT Machine Tools Kafo Double column install quality foundations and anchoring is key

Next comes the assembly of the main columns. These are the backbone of the Kafo Double Column machining centre, designed to support the significant weight and stress of the machining operations. Watching the columns being hoisted into place is both thrilling and awe-inspiring. It requires not just physical strength but also precise coordination and timing. Every bolt and screw must be tightened to exact specifications to ensure the structural integrity of the machine.

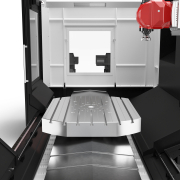

Once the columns are secure, the installation of the crossbeam begins. This critical component spans the width of the machine, connecting the two columns and providing additional stability. The crossbeam must be perfectly aligned to ensure the machine operates with the highest level of precision.

As the machine takes shape, the complexity of the installation process becomes more apparent. The engineers work methodically, connecting the various components with a level of expertise that only comes from years of experience. Wiring and hydraulics are integrated, ensuring that the machine’s systems are ready for operation. Each connection is double-checked and tested to prevent any issues that could arise during the machine’s operation.

The final steps of the installation involve geometric alignments and calibrating the machine. This process ensures that the Kafo Double Column machining centre will operate with the precision required for high-quality manufacturing. The engineers run a series of tests, adjusting settings and making fine-tuned adjustments to perfect the machine’s performance. This stage of the installation is crucial, as it determines the overall accuracy and reliability of the machine for years to come.

Investing in your workforce is just as important and the machine, extensive training is always given to ensure the operator/programmer/setters are fully converse with the new machine and control.

Watching this entire process condensed into a two-minute time-lapse video is both mesmerizing and educational. It provides a unique glimpse into the world of advanced manufacturing and the incredible effort that goes into installing such a machine. The dedication and skill of the engineering team are evident in every frame, highlighting the human element behind the technology.

In the end, what stands before you is a fully operational 5m x 4m Kafo Double Column machining centre, ready to take on the most challenging machining tasks. This machine represents the pinnacle of engineering and manufacturing, and its installation is a testament to the expertise and precision of TDT Machine Tools. Through this video, you can appreciate the intricate dance of logistics, engineering, and teamwork required to bring such a project to life.