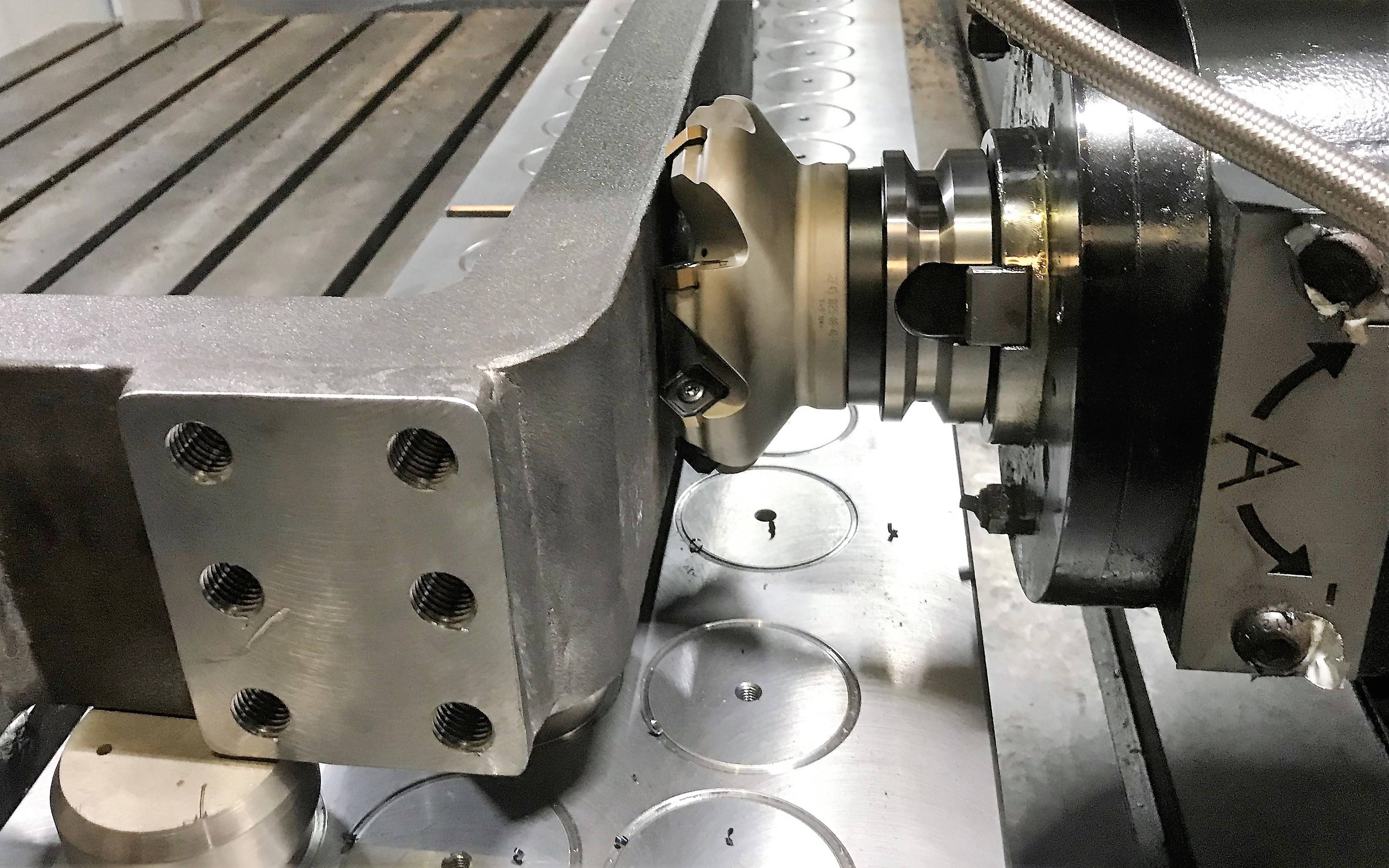

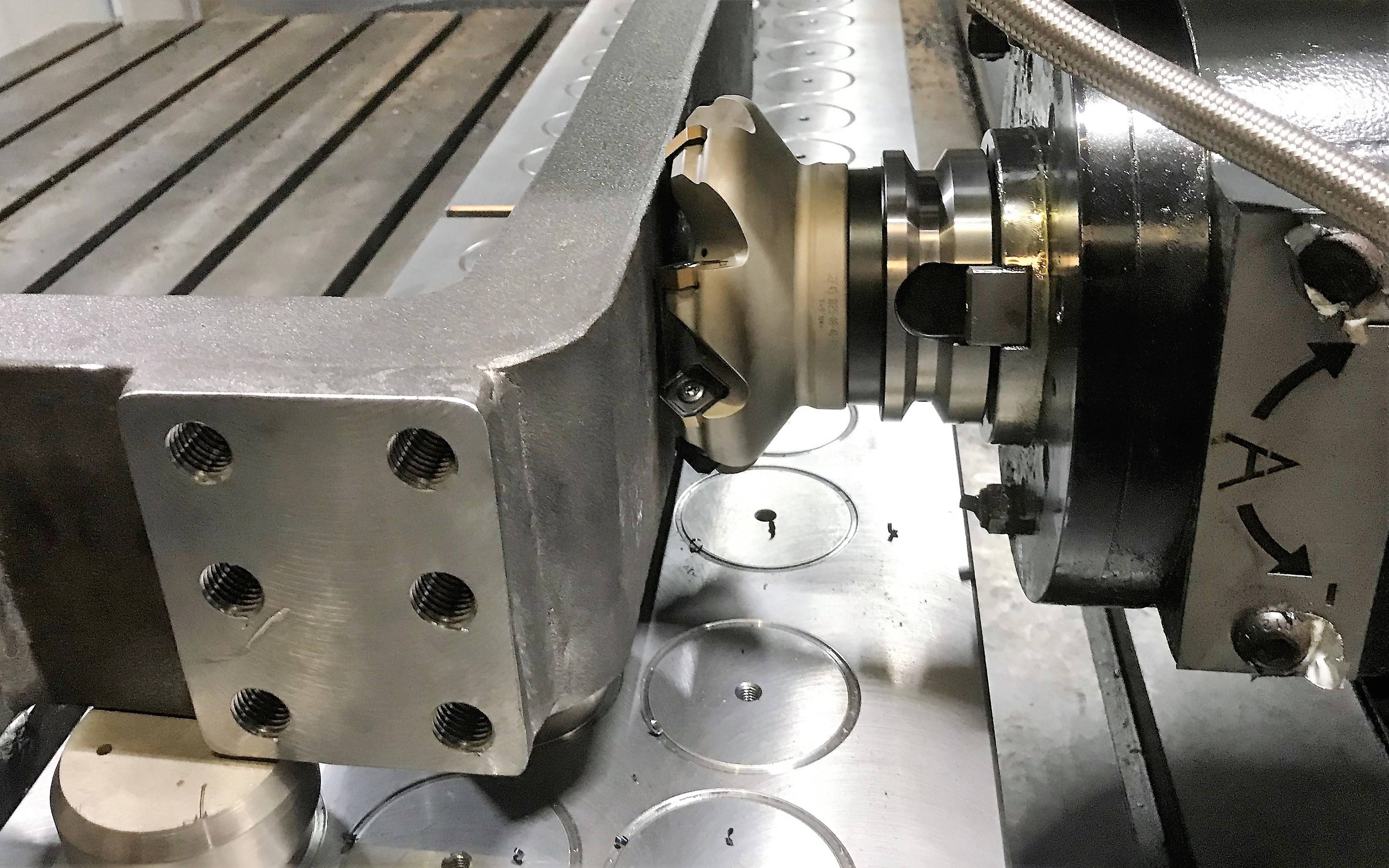

Tecnomagnete workholding 5mm x 120mm cut in high alloy steel

Using Mill-Tec GRIP 310 workholding, a Kafo KMC double column machining centre cuts through high alloy steel, 5mm depth of cut by approx 120mm wide with ease. The component is held to the table by magnetic force only.

Scroll down to see the video.

The GRIP patent revolutionises the concept of magnetic clamping on milling machines and machining centers; finally you can anchor everything uniformly, or anchor between the workpiece and the magnetic surface of reference and between the magnetic system and the machine table.

With MillTec the clamping force is distributed uniformly over the entire contact surface without any compression and deformation of the piece.

Using a combination of fixed and mobile pole extensions, it creates a flexible magnetic base that can clamp itself to the workpiece and secure it firmly. The new mobile extensions RMP make such operations even more simple and practical on uneven workpiece surface.